TEJAS Tubular Accessories

PIPE SERVICES

Pipe Inspection and Recondition 2 3/8" - 4 1/2"

Field Service Center:

2100 Co Rd 115, Alice, TX 78332

Method: Total Inspection and Reconditioning Pin-BOX (Rechase Method) under API 5CT Standards *

Thread: EUE, NUE, Two Step Type: ERW or SML

Diameter: 1-1/4", 1-1/2", 2-3/8", 2-7/8", 3-1/2", 4-12" * Grade: J-55, L-80

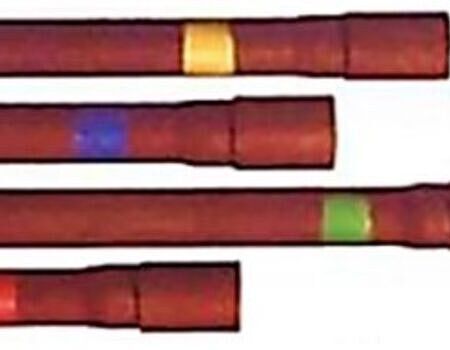

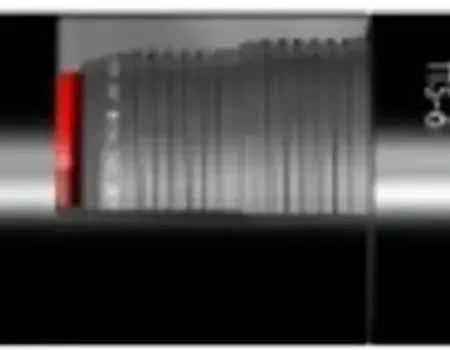

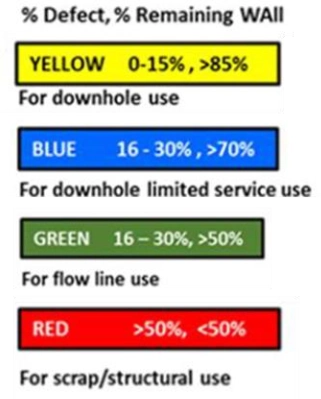

* COLOR CODE CLASSIFICATIONS for USED PIPE

CLASS 2: Yellow Band 0-15% bodywall reduction (85% minimum remaining)

CLASS 3: Blue Band 15-30% bodywall reduction (70% minimum remaining)

CLASS 4: Green band 31-50% bodywall reduction (50% minimum remaining)

CLASS 5: Red Band +50% bodywall reduction (les: than 50% remaining)

Portable Pipe Testing Service

TEJAS TUBULAR PORTABLE PIPE TESTING SERVICE

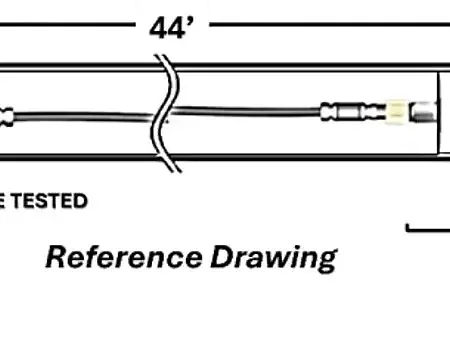

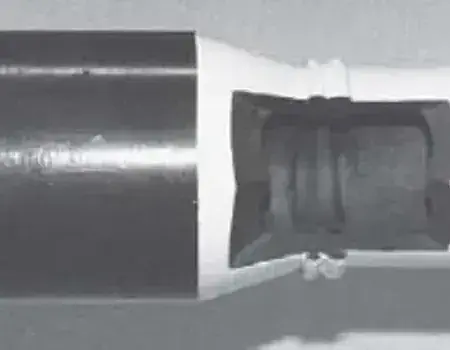

Size range from 1.660” thru 24” OD Length 20 to 48 Ft

- Internal Pressure Hydro Testing on Threaded and Coupled Pipe or Plain Ends.

- Hydro Test Pressure up to 80% of the tube body internal yield strength according to API Standards – OR- testing beyond API Specs up to 20,000 Psi based on customer specification.

- Pressure Testing Hold Time as per customer request with a minimum 5 seconds.

- Internal Test Tool set-up is based on ID pipe to be tested.

- Testing Service include OD Reading before and after testing, stencil and tallying.

- Ultrasonic Weld Line Inspection after test per customer request.

- Customer Testing Service Requirements: Space for Equipment Testing, Forklift Service for loading/unloading pipe from entry/outlet rack and water supply.

- Testing System available for permanent needs – customized design and build.

DOES YOUR PIPE PASS THE TEST?

Internal Test Tool for Pipe 24”OD x 42Ft

Tejas Tubular Oilfield Services is related to Tejas Tubular Products who is in business since January 25th, 1990

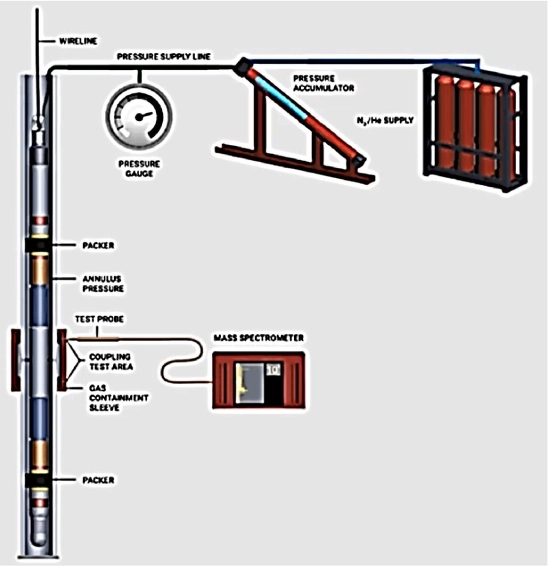

PRESSURE TESTING

INTERNAL TESTING

Internal Gas

- New/used premium completion tubing

- Alloy or chrome

- Integral joint and T&C premium

- High pressure, critical tubing string

- Available in combination with full joint water test

- 1" thru 13 3/8" connection only

- Up to 20,000 psi

Internal Hydrostatic

- Full joint - singles, double, triples

- New or used steel tubulars

- All type of connections

- Internal plastic coated tubulars

- 1" thru 4 1/2" full joint

- 5" thru 24" connection only

- Production Tubing

- Production Casing

- Liners and tie-backs

EXTERNAL TESTING

Tubing

- Injection/frac strings

- Work strings

- Production tubing

- 21/16" thru 4 1/2"

- Connections only

- Two-step, EUE and premium connections

Casing

- Connections only

- All type of connections

- Storage, disposal and injection wells

- 4 1/2" thru 13 3/8"

PORTABLE RACK FOR INTERNAL PIPE TESTING (API-5L , API-5CT)

Pipe Length Range R1 (18 - 22 ft), R2 (27 – 32 ft) , R3 (33 - 45ft)

Workstrings

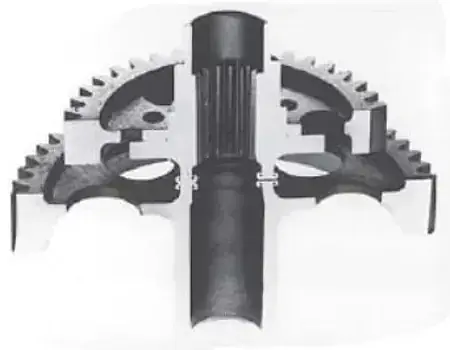

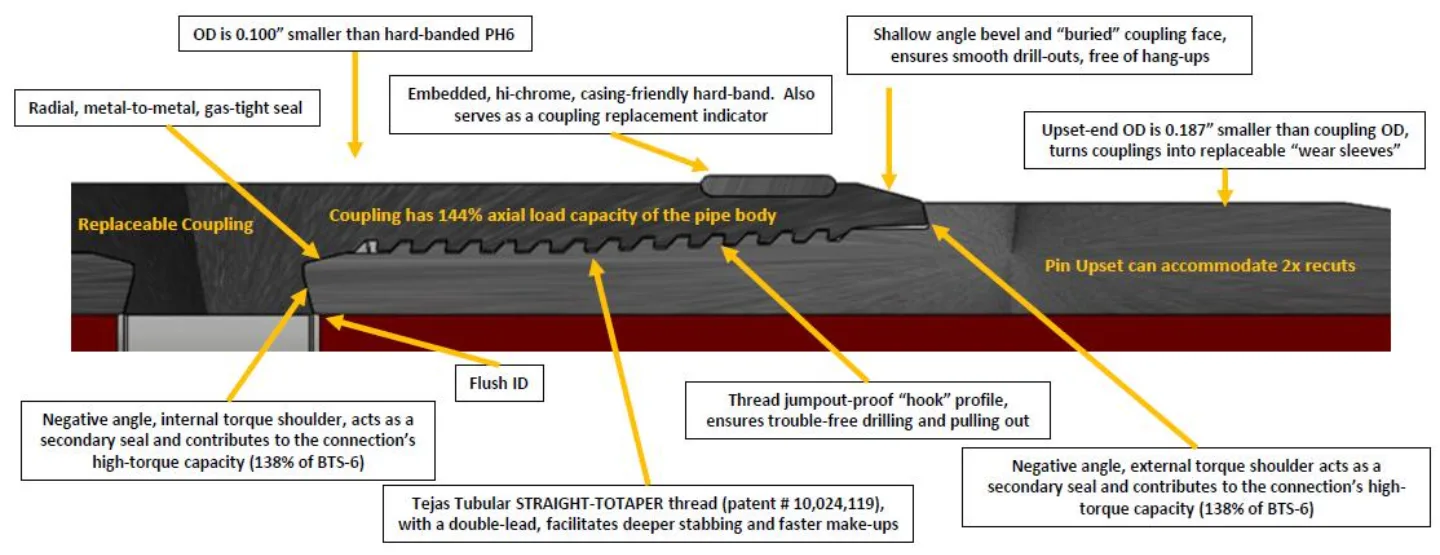

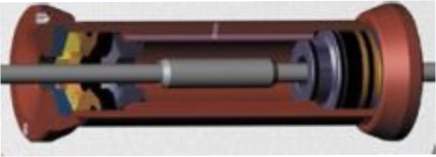

TEJAS WorkString Connections

not just another PH6 lookalike

The TEJAS Two-Step 6-pitch (TTS-6 Black) workover connection, integrates two very well established technologies in the O&G industry, the PH6 premium workover connection and the drill pipe inertia welding/bonding method.

This merger introduces a series of benefits in the TTS-6 Black design, starting with customizability, regarding the tool joint dimensions and tool joint / tube body grade combos, moving to the differential advantage of increased number of re-cuts and ending with refurbishing and extending the life of decommissioned tubing, by replacing worn end-upsets, provided tube body is still functional.

inertia welding is not welding

Welding processes can be classified into two main categories: 1) Liquid-phase welding (e.g. all fusion welding processes like arc, laser, electron beam welding) and 2) Solid-state welding (e.g. forge welding, friction stir welding, inertia welding, explosive welding, solid-state diffusion bonding).

In the former, bonds are established by the formation and solidification of a liquid phase at the interface, whereas in the later, applied pressure has a key role in bringing together the surfaces to be joined within interatomic distances.

Solid-state welding has been used for more than a thousand years. Japanese and Damascus swords were formed by heating, folding and hammering a strip of steel hundreds of times, until layers were bonded together …

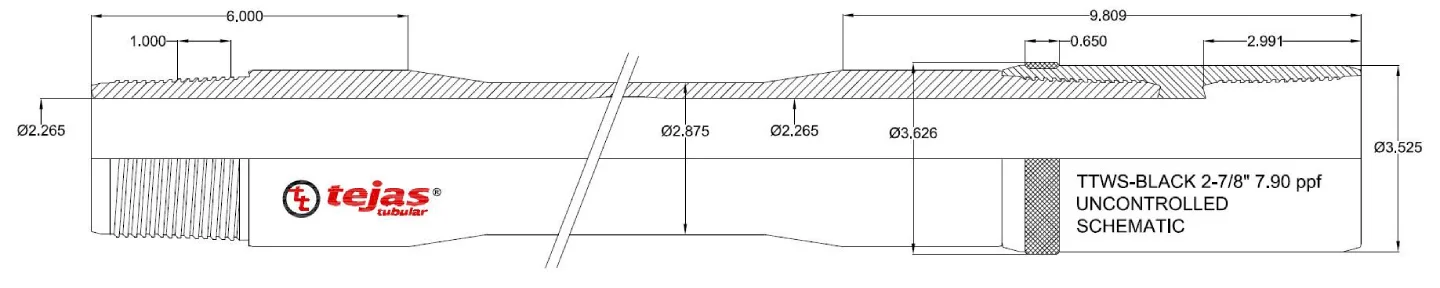

original WorkString T&C design

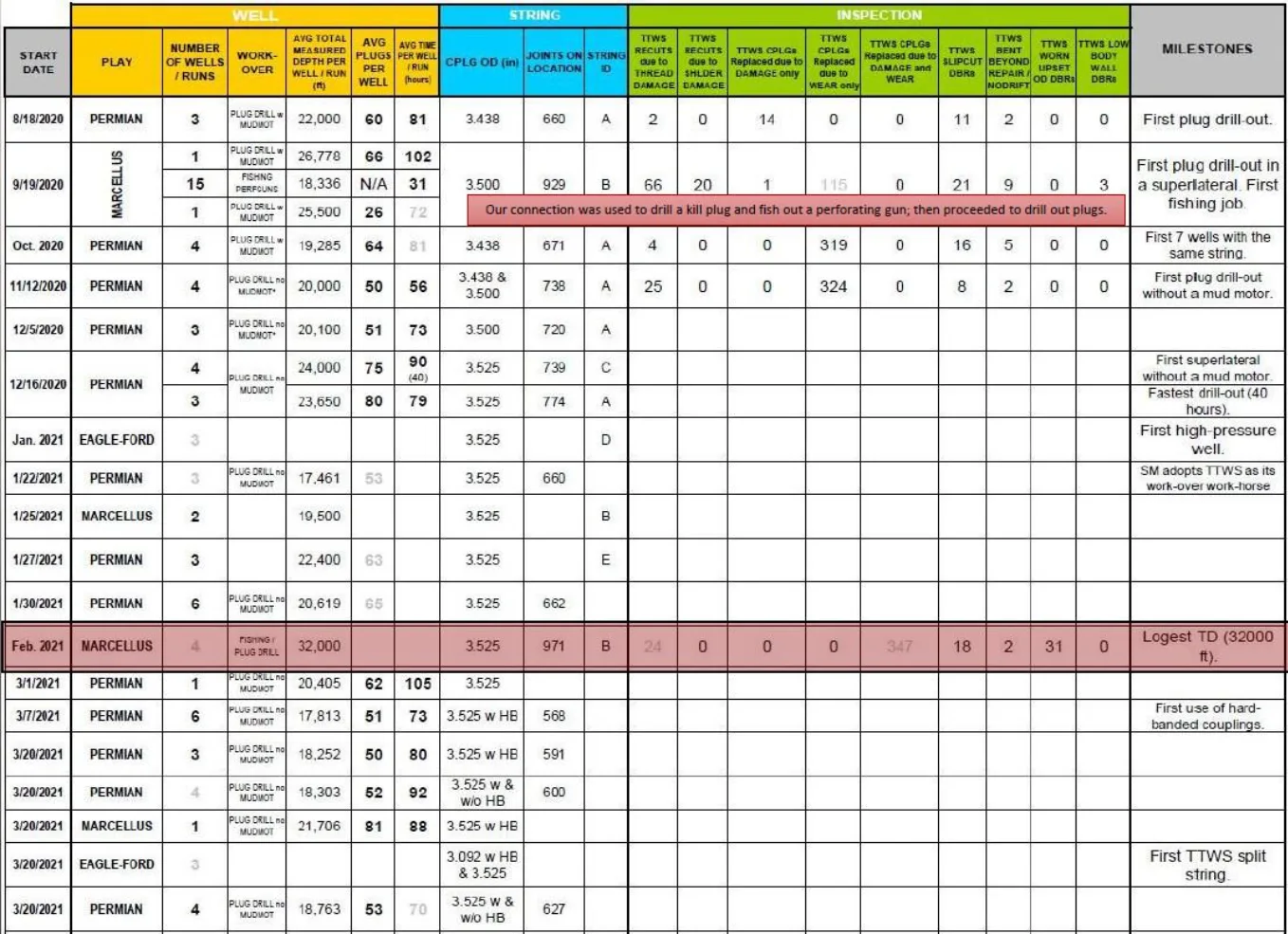

The TEJAS TUBULAR WORK STRING (TTWS) connection, was designed to address the need for an ultra hi-torque workover connection, that can reliably and economically tackle the present superlateral and future hyperlateral wells, that the O&G industry is moving towards.

The design combines a replaceable coupling concept, in order to extend tubing wear life, with a highly resilient, ruggedized thread incorporating locking/negative engagement angles and multiple torque shoulders …

but let’s have a closer look to this connection’s features and benefits …

features & benefits

- Rotating / Operating Torque exceeds the capacity of even the most powerful swivel

- High-speed rotating above 150 rpm w/o mudmotor, for fast drill-outs

- Long-reach frac-plug drill-out string, for the longest superlateral wells (32k ft TD drilled)

- Above 100% pull / push / torque efficiency, for demanding fishing operations

- Self-aligning long pilot and double-start thread, for fast and easy stabbing / makeup

- Negative-angle, self-locking torque shoulders and thread load flanks, that eliminate jump-outs

- In the absence of HB, replacing worn couplings way more economical than IJ designs

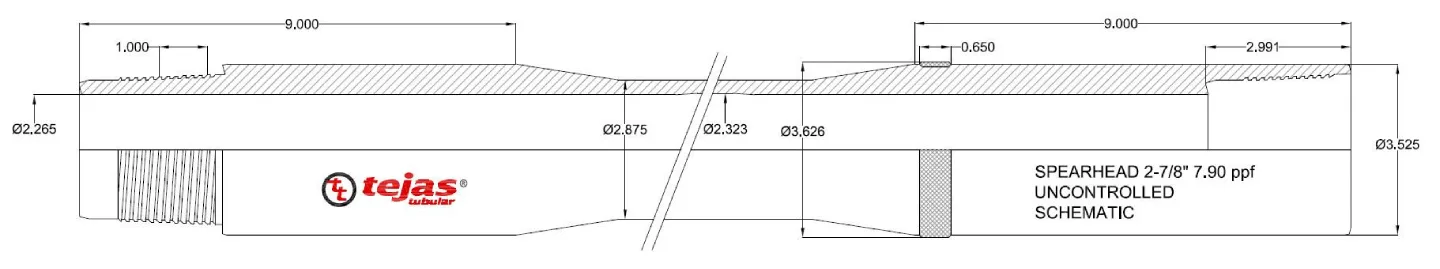

SPEARHEAD

In the SPEARHEAD connection, which is the latest TEJAS workover string connection design, we have merged the proven TTWS hi-torque thread design with the inertia-welded integral-joint concept.

SPEARHEAD retains all the benefits of TTWS, with the added benefits of, (a) a customizable in regards of OD, length and material tool joint, (b) increased number of re-cuts and (c) reanimating scrapped tubing due to compromised upset ends (no more re-cuts or worn out OD) and turning it to a premium workover tool, by retrofitting it with SPEARHEAD tool joints.

SPEARHEAD runs as fast and easy as your standard PH6, but has a much longer reach, due to its extreme torque capacity. And in wells that are not as long, it will save you money, because you can run it fast and hard w/o the need for a mud motor. In all respects it is the ultimate workover rig tool.

TTWS T&C vs. SPEARHEAD IJ

Oil Field Services

TEJAS TUBULAR, Inc. is an USA company, established on 1990 in Houston, TX dedicated to the manufacturing and processing OCTG API-5CT pipe and accessories; has processed more than 50 million joints of tubing or casing trading their products all over.

As an Oilfield Services Tejas Tubular offers at the Rig Area, Casing & Tubing Make-up (Hydraulic Power Tongs Capabilities 2-3/8” to 20”) with Computerized Torque Turn, On site Hydrostatic and Helium Test Tubular Pressure Testing on Tubing and Casing (Internal and External) and Pipe Services as Pickup & Laydown, Pipe Cleaning, Drift and Tally Pipe.

PROFESIONAL AFFILIATIONS

CASING & TUBING MAKEUP SERVICES

Pull & Run Equipment & Services

- Casing: 4 ½” – 20”

- Tubing: 2 3/8” – 4 ½”

Computerized Torque-Turn Services

- CT4500 Tong Mounted

- CT3000 Remote Torque-Turn Monitoring

PRESSURE TESTING

Internal Testing

- Hydro 2 3/8” - 24” 20,000

- Helium 2 3/8” - 13 3/8” 20,000

External Testing

- Hydro 2 3/8” – 13 3/8” 15,000

- Helium 2 3/8” – 13 3/8” 15,000

Portable Rack for Internal Pipe Testing

- Testing Plain End or Threaded Pipe 2 3/8” - 24” 20,000

PIPE SERVICES

Pick Up & Lay Down Machines

- Tubing 16 Ft Reach

- Casing 26 Ft Reach (Up to 16” Casing)

- Pipe Cleaning, Drift & Tally 2 3/8” - 24”

CASING & TUBING MAKEUP SERVICES

Pull & Run Equipment & Services

- Casing 4 ½” – 20”

- Tubing 2 3/8” – 4 ½”

Computerized Torque-Turn Services

- CT4500 Tong Mounted

- CT3000 Remote Torque-Turn Monitoring

RECOMMENDED FOR

- 8 Round EUE

- Hydril CS, PH6

- Generic Two Step

- Hydril Wedge Thread

- Modified Seal Ring Couplings

RECOMMENDED FOR

- T&C Premium Connections

- High Alloy & CRA Tubulars

- Flush and Near Flush Connections

- Internal Shouldered Connections

- Thin-wall Tubulars