Bucking Units

A bucking unit (also known as a casing bucking unit or bucking machine) is a specialized piece of equipment used in the oil and gas industry primarily for threading and unthreading pipe connections.

A bucking unit (also known as a casing bucking unit or bucking machine) is a specialized piece of equipment used in the oil and gas industry primarily for threading and unthreading pipe connections.

These units are essential for preparing pipes and casings before they’re run into oil and gas wells. Here’s how they work and what they’re used for:

Key Functions of a Bucking Unit:

-

Threading and Unthreading: The main purpose is to make up (tighten) or break out (loosen) threaded connections on pipes, casings, and tubing used in oil wells.

-

Torque Application: Bucking units apply precise torque to properly connect pipe sections according to manufacturer specifications, ensuring leak-proof connections that can withstand downhole pressures.

-

Connection Preparation: They’re used in pipe yards or on drilling sites to prepare pipe sections before they’re lowered into the wellbore.

How Bucking Units Work:

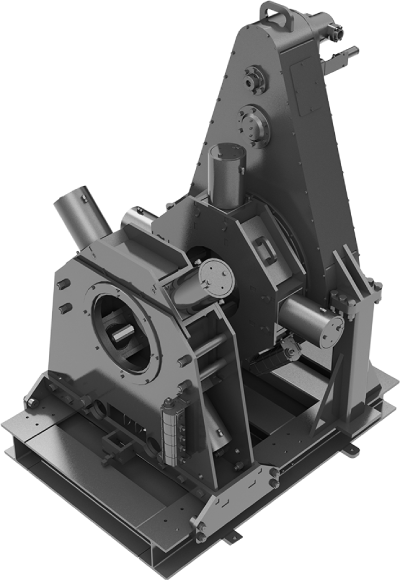

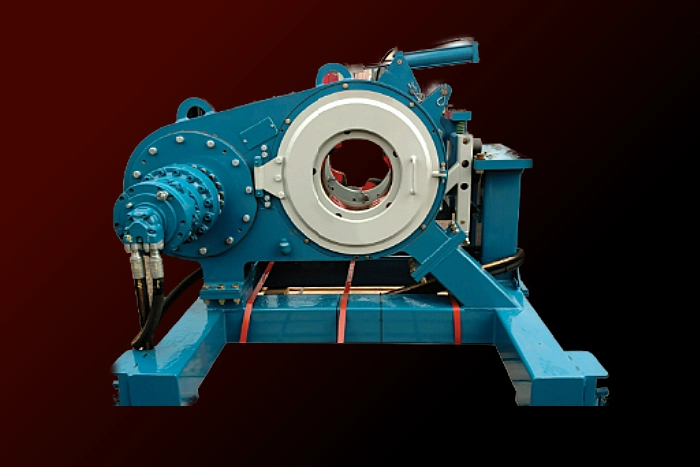

The typical bucking unit consists of:

- A sturdy frame structure

- Hydraulic power system

- Two opposing heads (one stationary, one rotating)

- Pipe-gripping mechanisms

- Torque measurement systems

During operation, one pipe end is held stationary while the other is rotated with precise torque to either tighten or loosen the threaded connection.

Applications:

- Casing Preparation: Making up casing connections before running them into the wellbore

- Tubing Work: Connecting production tubing joints

- Drill Pipe Maintenance: Breaking out connections for inspection or replacement

- Thread Cleaning and Inspection: Facilitating thread maintenance and inspection

Bucking units are critical for maintaining the integrity of the entire well system, as improperly connected pipes can lead to leaks, environmental issues, or even catastrophic well failures.

See Our Partners' Bucking Units

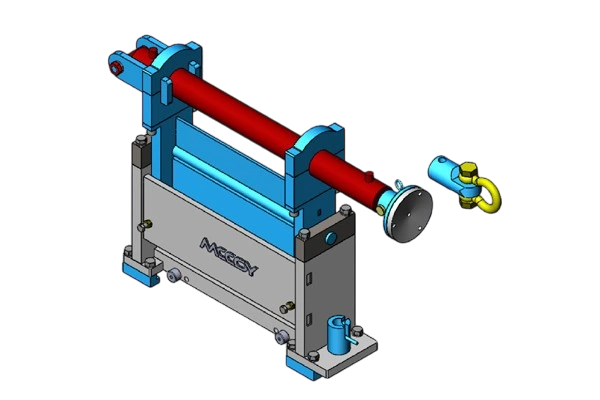

McCoy Global

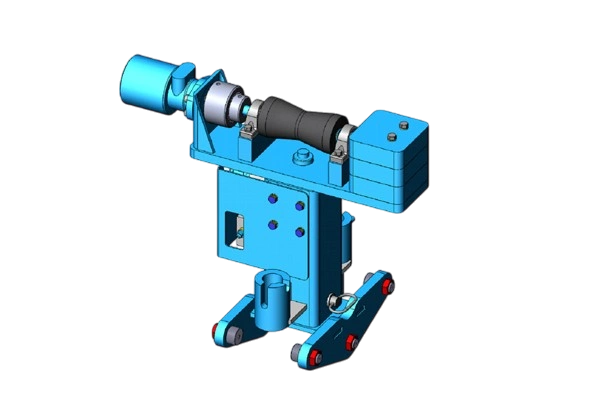

Continuously Rotating Bucking Unit

See The Technical MenuCall Us Today!

Standard Accessories

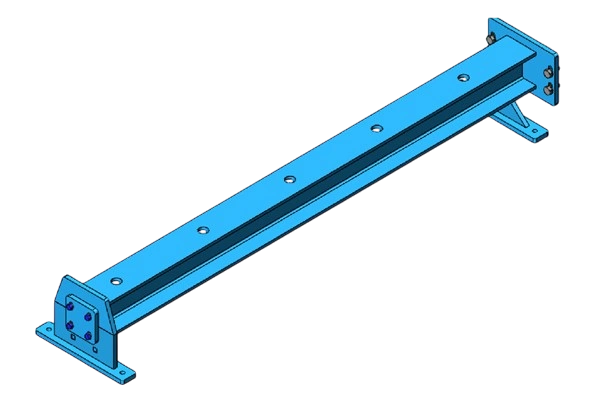

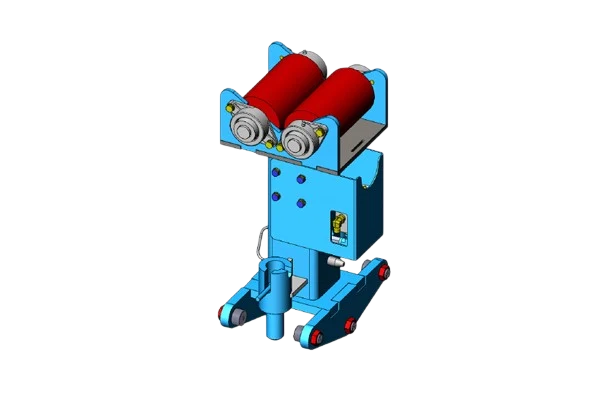

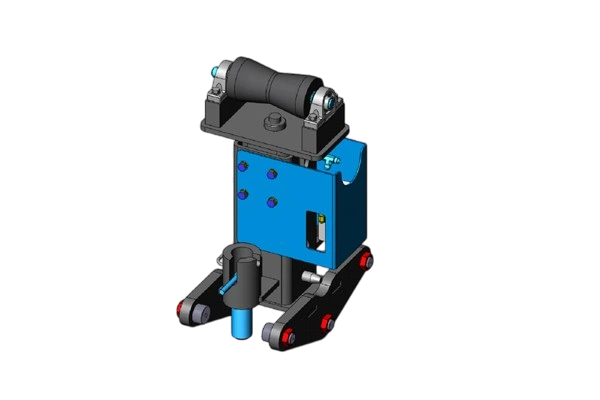

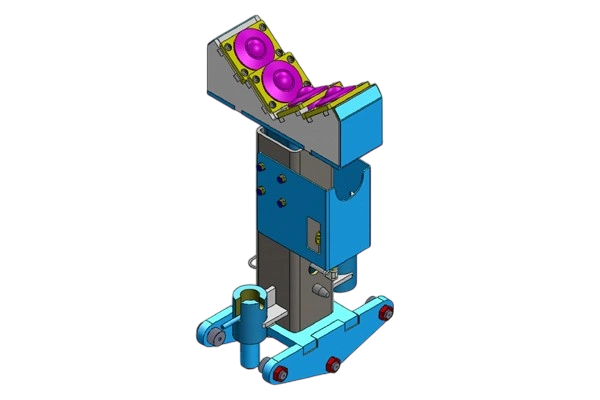

HYDRAULIC SUPPORT STAND

HYDRAULIC POWERED V-ROLLER SUPPORT STAND

HYDRAULIC NON-POWERED V-ROLLER SUPPORT STAND

HYDRAULIC TRANFER BALL ROLLER SUPPORT STAND

PUSH PULL