Dual Flapper

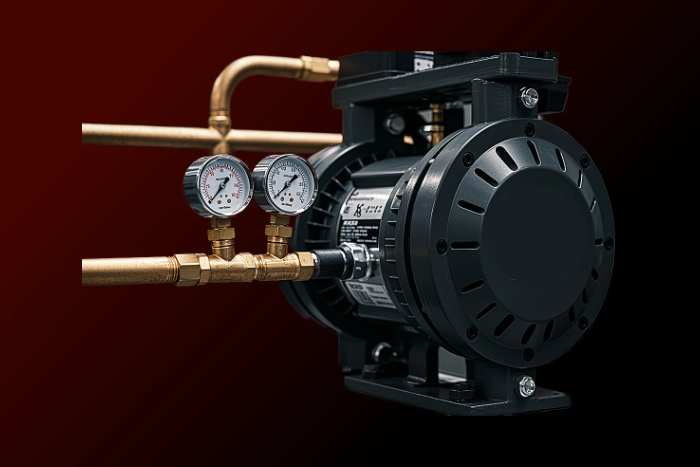

In the oil industry, dual flappers are specialized valve components used primarily in downhole tools and wellhead equipment. They serve important functions in controlling fluid flow and maintaining pressure integrity.

In the oil industry, dual flappers are specialized valve components used primarily in downhole tools and wellhead equipment. They serve important functions in controlling fluid flow and maintaining pressure integrity.

Dual flappers consist of two hinged flapper discs that work in tandem to provide redundant sealing capabilities. Here’s how they’re typically used:

-

Downhole Safety Valves: Dual flappers are installed in subsurface safety valves (SSSVs) to provide two layers of protection against uncontrolled flow from the well. If one flapper fails, the second remains as a backup.

-

Check Valves: They prevent backflow in pipelines and wellbores, with the dual-flapper design providing additional reliability compared to single-flapper systems.

-

Completion Equipment: In production tubing strings, dual flappers help control flow direction and can isolate sections of the wellbore when needed.

-

Wellhead Components: At the surface, dual-flapper assemblies may be incorporated into blowout preventers (BOPs) or other pressure control equipment.

The main advantages of dual flappers include:

- Enhanced reliability through redundancy

- Improved sealing capability under varying pressure conditions

- Better protection against debris that might prevent complete closure of a single flapper

- Extended service life in harsh downhole environments

Would you like more specific information about dual flapper applications or their mechanical design?