Slip Inserts for Oil Rigs

If you’re working on an oil rig, you know how important it is to have reliable equipment at every stage of drilling and well intervention. Slip inserts play a crucial role in these operations. These specialized components fit into the rotary slips assembly on the rig floor, helping you safely grip and suspend drill pipe, casing, or tubing in the wellbore.

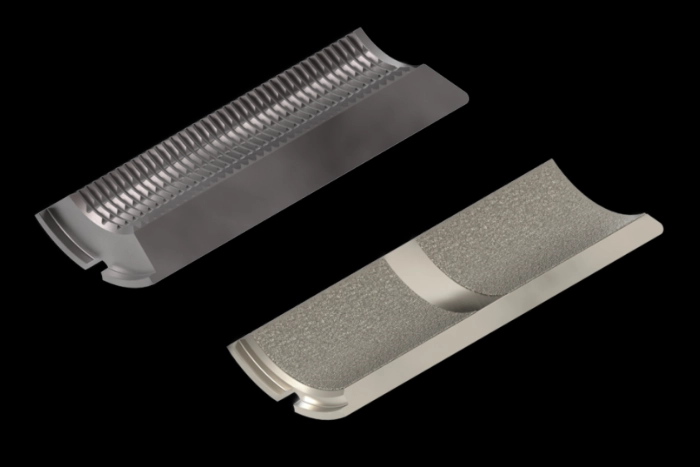

Designed with a wedge shape and interior teeth or gripping elements, slip inserts work together in a circular arrangement. This design allows them to hold pipe securely, even under the demanding conditions of the oilfield.

How Slip Inserts Work

-

When you need to suspend drilling pipe in the well—such as when adding a new joint—the slip assembly is placed around the pipe.

-

The slips are then set into the tapered slip bowl in the rotary table.

-

As the slips move downward in the bowl, the tapered design causes them to move inward against the pipe.

-

The teeth or gripping elements on the slip inserts bite into the pipe’s surface, providing a secure hold.

-

The weight of the pipe pushes the slips further into the bowl, increasing the gripping force through mechanical advantage.

Types and Characteristics

- Slip inserts are available in multiple sizes to fit a variety of pipe diameters.

- They’re manufactured from hardened steel or alloys, built to handle high loads and tough conditions.

- The teeth patterns are designed to match the type of pipe being gripped—some inserts have aggressive teeth for drill pipe, while others use a gentler pattern for casing to help prevent damage.

Because slip inserts are exposed to significant forces, they do wear down over time. Regular inspection and timely replacement are key to maintaining safe and efficient rig operations. If you have questions about slip inserts or need guidance on inspection and replacement, our team at Longwood Energy Services is here to help.

Click to Call Us for a Quote

Thank you for letting us earn your trust.